Table Of Content

- Introduction to Model-Based Design: Modeling and Simulation with Simulink

- Trajectory Tracking Control Design for 4WS Vehicle Based on Particle Swarm Optimization and Phase Plane Analysis

- System Requirements

- Measurement setup

- Products

- A need for an efficient annotation and deep learning microstructure segmentation

For HPB the magnitude of G is decreasing which suggests an increase of the neck’s radii during sintering. The sinter process also causes a reduction of the particles’ convexity leading to a decrease of the mean curvature for the higher porosity material HPB (Fig. 3d). Its negative value indicates that necks with small radii saddle-like surfaces are prevalent. The positive MHPA of 2.18 μm−1 shows that the incidence of convex structures is quite dominant. Therefore, spherical geometries of HPA’s nanoparticles are still abundant. This type of surface illustrates that HPA is still in an early stage of sintering50; therefore, the particles are just starting to coalesce and their necks are newly formed.

DNV, Damen And NAPA Use 3d Model-Based Approval To Streamline Ship Design Approval - Marine Insight

DNV, Damen And NAPA Use 3d Model-Based Approval To Streamline Ship Design Approval.

Posted: Mon, 26 Jun 2023 07:00:00 GMT [source]

Introduction to Model-Based Design: Modeling and Simulation with Simulink

The data set includes information on pollutants such as PM2.5, PM10, SO2, NO2, CO, and O3 and environmental information such as temperature, humidity, pressure, rainfall and wind speed. Moreover, increasing the VBIAS shifts the voltage transfer curve in the right direction, which can be useful for post-fabrication tuning of the static noise margin, depending on the local VT and variability values10. Figure 2a shows the voltage transfer curves in which VBIAS equals twice VDD for pseudo-CMOS logic. Figure 2b shows the logarithmic power consumption curves with respect to Vin for all logic styles, in which a difference in static power consumption of more than six orders of magnitude is observed. The static power when Vin is logic 0 stems from the leakage of n-type devices because of the VT difference in technologies.

Free Model-Based Development Software - Digital Engineering 24/7 News

Free Model-Based Development Software.

Posted: Wed, 07 Nov 2018 08:00:00 GMT [source]

Trajectory Tracking Control Design for 4WS Vehicle Based on Particle Swarm Optimization and Phase Plane Analysis

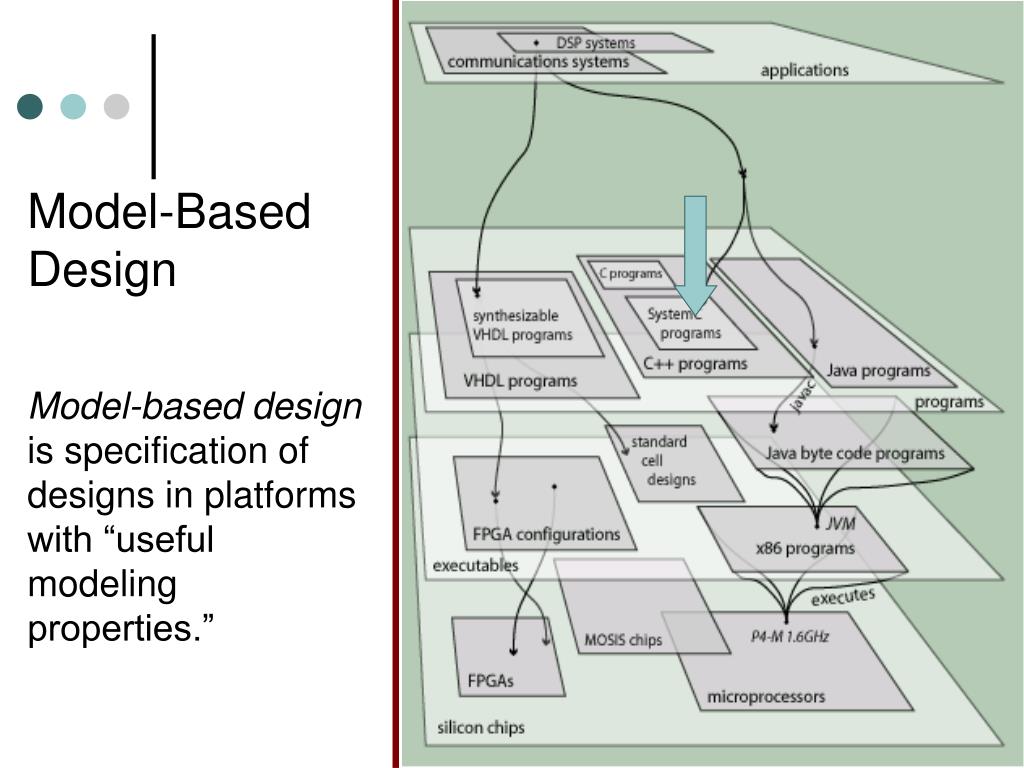

Owing to the low-process temperatures, a thin flexible substrate on top of a glass carrier can be used for manufacturing. The main advantage of these technologies is the scalability of the technology because of the available lithography toolsets, as it will enable high-density flexible circuits. The channel lengths are typically smaller for those foundries—sub-micrometre ranges—compared with the panel-based approach, with reduced overlay leading to faster operating transistors with smaller parasitics. There is a limitation in scaling depending on the semiconductor technology, whether it is available in an amorphous or polycrystalline state. Amorphous semiconductors, such as amorphous indium–gallium–zinc oxide (IGZO), have the potential for (deep) sub-micrometre channel lengths and are already being developed for back-end-of-line applications on top of Si CMOS20. A digital-modeling environment also creates a common standards-based approach to documenting the system that can be programmatically validated to remove inconsistencies within the models and enforce the use of a standard by all stakeholders.

System Requirements

The hybrid-paste HPB shows the highest porosity and depicts a different behavior upon sintering. Hyper-parameters can largely affect the generalization ability of the CPU-GPU heterogeneous parallel SVR model. It is difficult to determine the appropriate values of the parameters through a priori knowledge and the process of manually tuning the parameters is very time-consuming. To make the model evaluation more accurate and credible, the particle swarm optimization algorithm was used to find the optimal values for the C and σ parameters in Eqs. The steps for parameter optimization of the CPU-GPU heterogeneous parallel SVR model using the particle swarm algorithm are as follows. The main parameters affecting SVR performance are penalty factor C and the radial basis radius of the RBF kernel function σ.

The transistor transfer characteristics for both technologies are shown in Supplementary Fig. The traditional photolithography equipment for those foundries exhibits critical dimensions in the micrometre range, yielding transistors with above-µm channel lengths. In 2015, Denise Duncan published an influential article advocating for the use of models for virtual prototyping within the Department of Defense.

Measurement setup

Notably, such an elicitation of physical descriptors or the microstructure features displays an essential requirement in material science. ML shows advantages to process complex and big microstructure data as well as to extract relevant morphological features obtained from SEM25 or tomography-based methods26. Recent studies show that deep learning algorithms are highly suitable for semantic image segmentation27.

Products

When done well, it allows engineers to iteratively de-risk product development by starting with the riskiest part of development when the cost to change is low, the ability to change is high, and the level of investment is still low. Development artifacts such as requirements went from being written on paper and shared amongst teams to being written as conceptual models. These conceptual models were higher level of abstraction representations of the system either in text or code.

A need for an efficient annotation and deep learning microstructure segmentation

The LTPS CMOS inverter consumes less power regardless of supply voltage because of its complementary structure. When effectively developed, a model-based design offers an enormous improvement in cost reduction and schedule acceleration by removing otherwise manual and burdensome overhead a documentation-based approach relies upon. We’ve long known the use of models has enormous benefits to bring a design to reality.

TFT technologies

Each row of the matrix has m kernel functions to be computed, with a minimum time complexity of O(mk). The kernel function operation is the most complex and time-consuming part of the SMO algorithm, and the kernel function values of the current two sample data need to be calculated in each iteration. Calculating each element in the kernel function matrix requires only two corresponding data corresponding to it x and xi and no additional sample data. Because there is no correlation between any two different elements in the matrix, this satisfies the conditions for parallelization.

Figure 3d depicts the G-M curvature joint distributions of the copper surfaces for different sinter stages. In the first (QI) and second (QII) quadrants, two tails extend to high mean curvature values. The changes of those tails with temperature indicate the change of the copper particles’ convexity. The copper particles’ local geometries at the lower sinter temperature, display mostly cup-convex surfaces resembling spheroidal structures49, therefore, their Ms are positive. As a result, the emerging tails in QI are getting less pronounced by increasing the temperature for all presented materials. The observed behavior is complemented with an increased number of cup-concave geometries indicated by more pronounced tails in QII.

Similarly, there’s plenty of grandiose vision of what’s possible with little about what is realistic when it comes to model-based design. This has created substantial confusion and a fair bit of skepticism as to what model-based workflows are capable of. Thus, the following series of blogs is intended to clarify much of this confusion from the perspective of Hiller’s own experience developing model-based workflows.

You can automatically generate code from a model and, when software and hardware implementation requirements are included, create test benches for system verification. Code generation saves time and prevents the introduction of manually coded errors. As the product development process goes on, the overall understanding of the system improves and system requirements can be iterated upon. However, all connections must be maintained and up to date for the development teams.

As the manufacturing industry moves towards a more digitally connected and efficient future, Model-Based Definition is at the forefront of this revolution, paving the way for more effective product development and manufacturing practices. By incorporating everything into the product definition, MBD aims to replace traditional 2D drawings with comprehensive 3D models. This involves attaching all the necessary geometric, dimensional, and other manufacturing information directly to the 3D CAD model, eliminating the need for separate 2D drawings.

Production will typically entail some form of human or driver in the loop testing in a real world environment. The goal is to test the end-to-end functionality with a human present and ready to take control in case of a safety event. At this stage, companies will evaluate the performance of the model against the performance of the product in the real world.

C is a general-purpose programming language and is highly suitable for embedded software because it is processor-independent, portable, fast, and offers direct access to memory management. While C is not as low-level as assembly language, it is generally less user-friendly than higher-level languages. Therefore, many companies will choose to use automatic code generation tools to streamline the process of converting the model to code.

No comments:

Post a Comment